product design for production 3D printer series

interaction design lead // design strategy • design leadership • UX vision • UX design • UI design • wayfinding • visual design • motion design • prototyping • design research

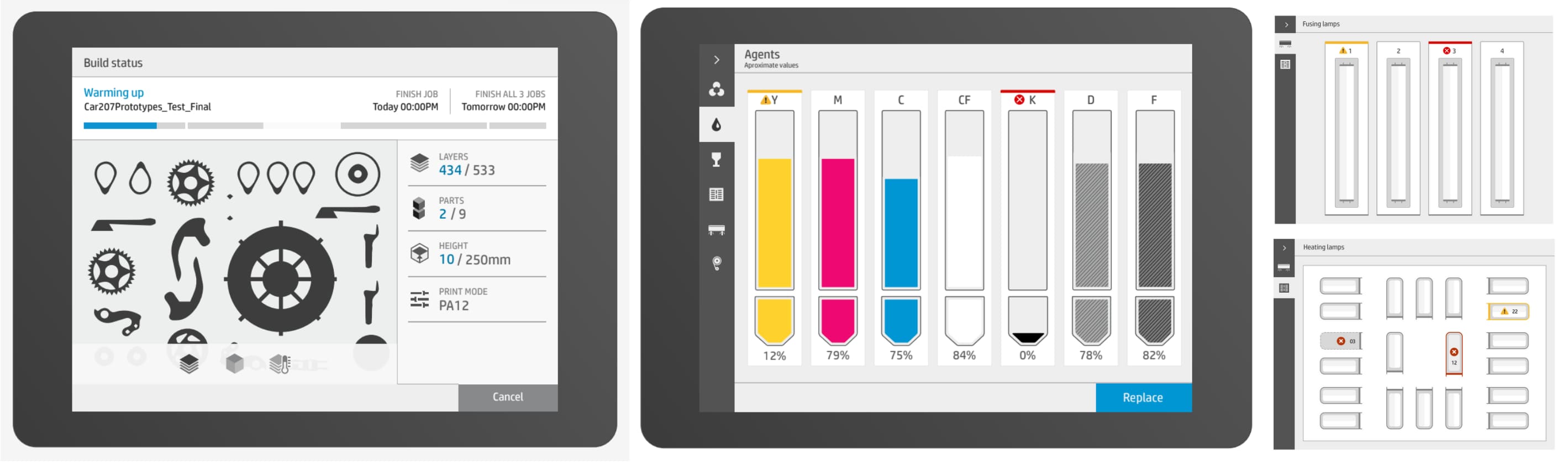

I led a team of world-class interaction and visual designers in crafting the end-to-end product experience for HP’s first fully integrated and first full-color Jet Fusion 3D printers, the Multi Jet Fusion 300, 500 and 800 Series. I collaborated closely with my design team as well as a global team of product design, UX research, industrial design, engineering, and product management to build this innovative user experience from the ground up. I was responsible for designing a new printer UI and updated software experience working with an existing design system, as well as the unique interaction and visual design of all physical touchpoints including beacons, lighting, iconography, and labeling of the printer and borgs.

This printer series has been celebrated by the VA, pediatric orthotics and prosthetics specialists, aerospace industry leaders such as Airbus, and manufacturing leaders such as ABCorp; and successfully became first in its class in both in-house production 3D printing and full-color Jet Fusion printing. It won the Red Dot Design Award in 2018.

« I still say HP developed the 580 for pediatric O and P [orthotics and prosthetics]. This machine has advanced my practice, but most importantly, the 580 improves the lives of so many patients. »

Dennis Richard, Orthotist at 3D Stability LLC

business goal

HP aimed and and succeeded at launching the first multicolor Jet Fusion 3D printer and first end-to-end production 3D printer, combining powder mixing, loading, printing, and recycling into one compact product, to be the first 3D printer targeting in-house production and development for labs, universities and SMBs.

user experience goal

As the first Jet Fusion printer to offer multicolor as well as integrated powder printing & reclamation, this product required innovative workflows across operation, error handling, supply management, and wayfinding. My focus was on establishing a deep understanding of the user needs and operating requirements of this printer, to optimize ease of use.

design process

01/ discovery and alignment

I collaborated with design partners, researchers, developers, engineers, and product managers to define the vision for this new 3D printing system, while it was being built from scratch. Leading a team of Interaction and Visual designers thorugh extensive research and analysis of the end-to-end user journey as well as hands-on experience with the product as it was engineered, I aligned with partners on the user needs, business objectives, and technical constraints that would inform the interaction, wayfinding, lighting and visual design strategy.

02/ definition and exploration

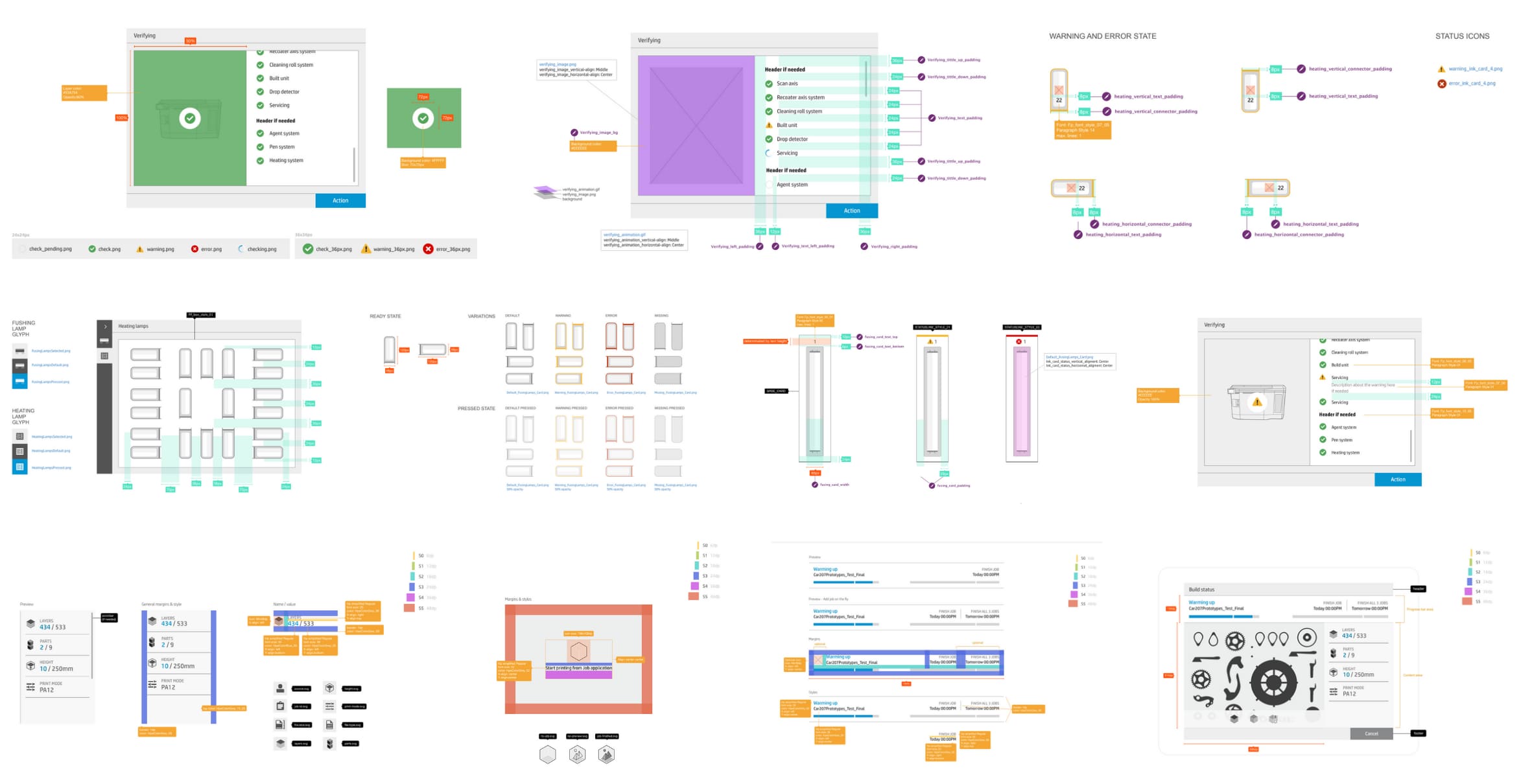

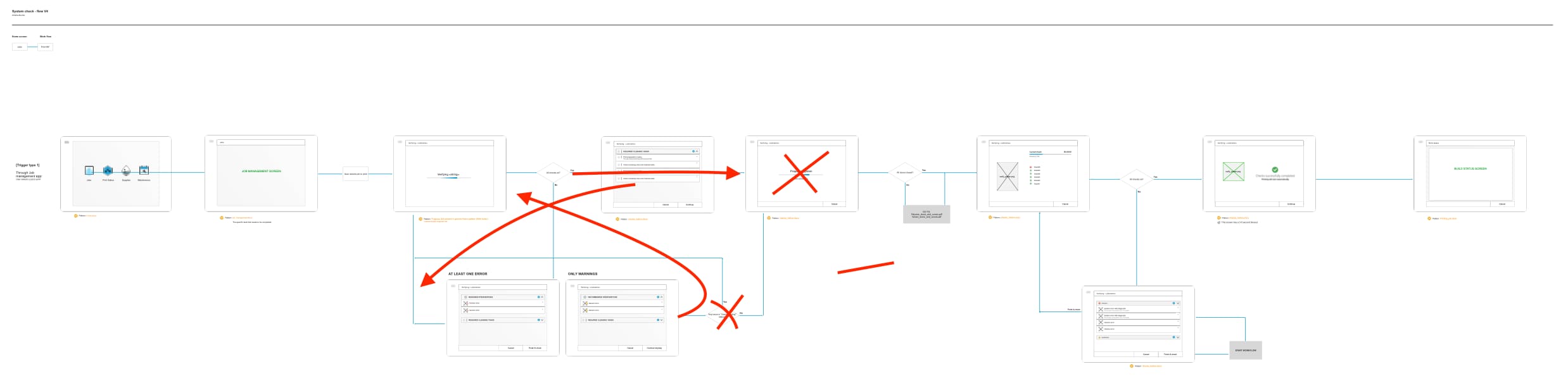

In addition to understanding the user target and needs, my team conducted in-depth research into current industrial 3D printing workflows, analyzing existing solutions and pain points. We worked continually with the engineers building this technology to gain an in-depth understanding of the printer and the user needs to maintain it. I led the team in developing wireframes, screen flows, interaction patterns, and wayfinding across printer and software, including physical wayfinding and visual touchpoints such as beacons, labels and lighting.

03/ validation and iteration

We conducted multiple rounds of extensive usability testing with end users, using a combination of pysical and digital prootypes to contextually simulate the UI, beacon and lighting experiences as we had users conduct tasks. In addition to guiding research requirements, I had the opportunity to run the research lab and conduct user interviews directly for multiple tests. This extensive testing supported the ongoing refinement of interaction patterns and processes, and the overall optimization of user workflows as the product evolved and took shape.

04/ delivery and implementation

Working closely with development teams locally and globally, I led our design team's creation and refinement of detailed interaction and visual design specs outlining the UI of the printer and accompanying software, as well as motion and visual specs of physical lighting and graphics. I continually advocated for a user-centered approach when adressing technical constraints, refining the experience to account for unexpected technical challenges, ensuring that the final product experience maintained a high level of design integrity despite working with complex technical constraints.